PSA oxygen plant from China factory with the features of low energy consumption and less space for installation

PSA oxygen making machine working principle: Different adsorption and diffusion between oxygen and nitrogen in ZMS and pressuring adsorption and decompressing desorption. Under the help of PLC programme ,nitrogen will be absorbed and qualified oxygen will be released. Because of the preferential adsorption quality of ZMS (zeolite molecular sieve), ZMS adsorbs nitrogen in the tower while pressuring so that the qualified oxygen is achieved. While decompressing, the process of desorption will release nitrogen as well as the ZMS is regenerated.

Because of the characteristic of low energy consumption and less space for the machine, the customers and users can benefit a lot from them. Thanks to the low energy consumption, it will cost little investment for the investors. Also, during the working process, the power of electricity will be enough for running.

Owing to the less space for placing the machine, it will take fewer land so that the saved one can be used for other purposes.

Technical features of PSA oxygen generator:

- PLC controlling system, operate automatically, steady performance, low rate of failures happening.

- Producing oxygen quickly, qualified oxygen can be made in 10 ~ 20 minutes .

- Nobody is necessary to stay around the machine because of the fully automatic operation of the equipment.

- Owing to the compact and solid structure of molecular sieve, the operational life span is longer.

- Low energy consumption can protect the environment and save the source in many ways.

- Less space for installation can reduce the covering area, and it can be used for some other aims. It will be more flexible for the customers.

- Compared with other method in producing oxygen, it will be safer.

Application fields:

PSA industrial oxygen generator can be widely used in oxygen-enriched combustion petrochemical industry, electric furnace steel making, paper making, glass production, making ozone, aquaculture, sewage treatment, aerospace and other industries and fields. Because different users have different requirements of the oxygen, SINCE provides personalized and specialized oxygen equipment so that the requests of different users can be fully met.

PSA oxygen generator system components and working process:

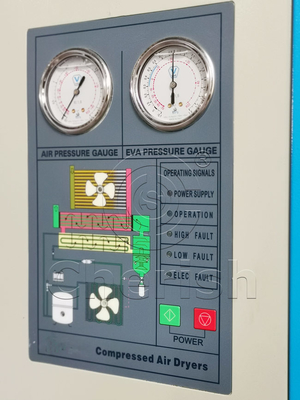

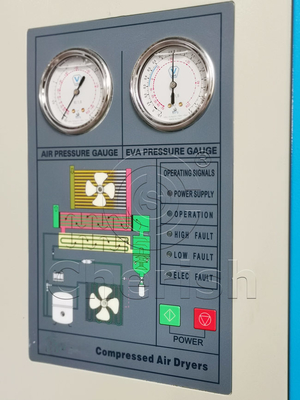

* Compressed air purification units: This part provides raw material for the whole system. The material is air so that the cost is not high and it is quiet friendly to the environment. It ensures the customers can get more benefit and brings less problems to the production of qualified gas.

* Air storage tank:The role of the air tank is to reduce the air pulsation of piston air compressor, improve the continuity and pressure stability of the output air flow, further precipitate and separate the water and oil in the compressed air, and ensure the continuous supply of enough air. Also, it can protect the compressor so it will serve for a longer time.

* Oxygen and nitrogen separation unit:There are two adsorption towers A and B which have special molecular sieve.When the clean compressed air enters into the tower A and flows through the molecular sieve, N2 is adsorbed, and O2 flows out from the outlet end of the adsorption tower.The molecular sieve will be saturated in tower A after some time of adsorbing and tower A automatically stop adsorbing. Then compressed air passes through tower B for absorption of nitrogen and production of oxygen , and molecular sieve in tower A will be regenerated in a short time and release the adsorbed nitrogen. These processes are controlled by a programmable logic controller (PLC). When the oxygen purity is lower than the rated one, PLC will evacuate the valve automatically to release the unqualified oxygen. It ensures that the unqualified oxygen will not go back to the pipeline.

* Oxygen buffer tank:The oxygen buffer tank is used to balance the pressure and purity of oxygen separated from the nitrogen-oxygen separation system to ensure the stability of continuous oxygen supply in case of the high pressure and output gas. Moreover, it can protect the control system and machine to prolong the service life.

Technical Parameters:

● Oxygen output——≤150Nm3/hr

●Purity——93%±3

● Pressure——0.3~0.4 Mpa

● Atmospheric dew point——≤-40℃

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!