Automation Control And Monitoring VPSA Oxygen Equipment Used In Glass Blowing & Neon Light Manufacturing

| Product name |

VPSA Oxygen Generator

|

| Oxygen delivery |

≤600Nm3/hr

|

| Purity |

93±3%

|

| Pressure |

0.2-0.3 Mpa

|

| Atmospheric dew point |

≤-60℃

|

Working Principle Description:

The VPSA (Vacuum Pressure Swing Adsorption) oxygen generator employs a series of steps to produce oxygen:

Air Compression: Ambient air is drawn in and compressed using a compressor, raising its pressure and concentration of oxygen.

Adsorption Towers: The compressed air is directed into adsorption towers containing specialized adsorbents like molecular sieves or activated carbon.

Adsorption Phase: The adsorbents selectively capture nitrogen molecules from the compressed air, allowing oxygen to pass through and become enriched.

Pressure Drop Desorption: As the adsorption capacity of the adsorbents reaches its limit, the pressure in the towers is reduced. This causes the adsorbents to release the trapped nitrogen molecules.

Oxygen Collection: The expelled nitrogen gas is vented out, while the oxygen-enriched gas is collected as the desired product.

Tower Switching: To maintain a continuous oxygen supply, the operation switches between adsorption towers. This ensures uninterrupted production while allowing saturated towers to regenerate.

By utilizing selective adsorption and pressure variations, the VPSA process effectively separates nitrogen from air, resulting in a high-purity oxygen output. This method offers versatility, efficiency, and adaptability, making it suitable for various industrial and medical applications.

Product Advantages:

● Automation control and monitoring: Modern VPSA oxygen equipment is usually equipped with automation control systems and monitoring equipment. These systems can monitor and adjust key parameters such as pressure, temperature, and gas flow to ensure stable operation and efficient performance of the equipment. At the same time, they can also provide fault diagnosis and alarm functions for timely maintenance and repair.

●Multiple gas source adaptability: VPSA oxygen equipment can adapt to multiple gas sources, not limited to air. It can handle mixtures of oxygen-containing gases, such as industrial waste gas, refinery exhaust gas, and chemical plant emissions. This adaptability of multiple gas sources makes VPSA oxygen equipment have broad application potential in the industrial field.

●Automatic fault recovery: Modern VPSA oxygen equipment typically has automatic fault recovery capabilities. When the equipment malfunctions or malfunctions, the automatic control system can detect and take corresponding measures, such as switching to a backup adsorption tower or issuing an alarm signal. This can reduce downtime and improve the reliability and stability of the equipment.

Technical parameters:

● Oxygen delivery: ≤600Nm3/hr;

● Purity: 93±3%

● Pressure: 0.2~0.3 Mpa

● Atmospheric dew point: ≤-60℃

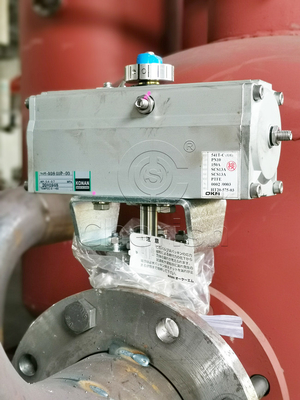

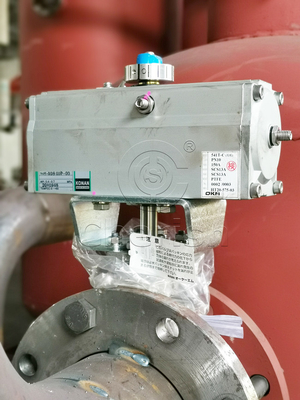

Product picture:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!